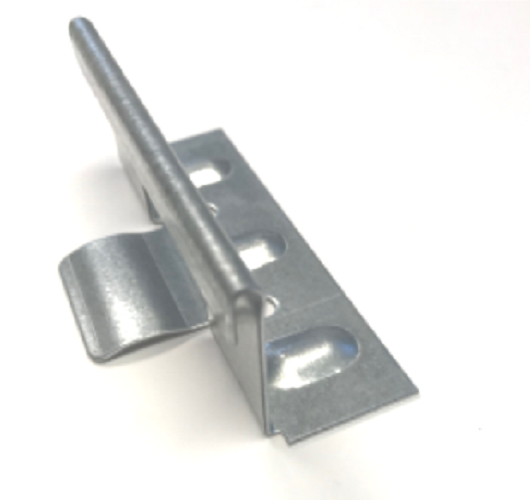

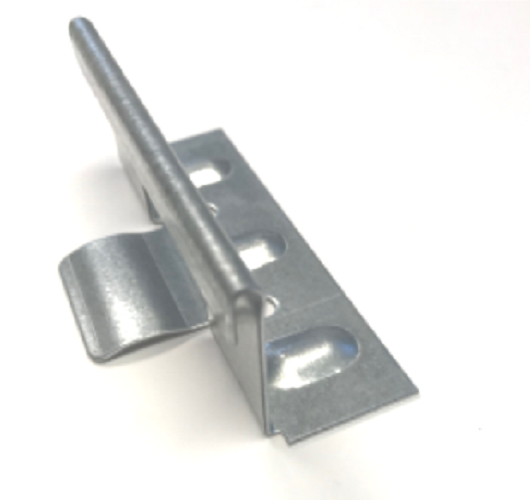

They fasten underneath the panel and out of view to keep the clean look of a standing seam roof.

Snap fit metal roofing.

If you love long clean lines and low slopes a snaplock metal roofing or siding panel is your dream come true.

Field seamed and snap lock.

It is also light and somewhat comfortable to wear on the roof.

The snap on metal roofing systems are not true standing seam roofs since they typically require no on site forming no hand forming or hand crimping.

Top sellers most popular price low to high price high to low top rated products.

We developed this free floating system to allow metal to expand and contract with temperature fluctuations and to keep you protected from wind rain snow and hail.

3 wide rib panel.

Snap on panels are ideal for use in roofing mansard and fascia applications.

It has a metal ring hammer snips holder on each side large pockets a special place to put a bulky tape measure and is otherwise rate small compared to other full size tool belts.

Snap lock is a type of standing seam metal roof panel that has a male and female leg that snap together.

Clips are used to attach the panel to the roof deck.

With our 1 5 tru snap panels you can create elegant rooflines without interruption and crisp accents that draw the eye.

This is being performed on our 2015 home show display in cedar rapids.

Snaplock metal roofing siding.

In stock at store today.

Maximum panel length is 35 and minimum panel length is 4.

There are two basic styles of panel for standing seam metal roofs.

Snap on panels are factory roll formed in continuous lengths.

They use factory made trim stock and various proprietary methods for interlocking the panels.

Watch as tri county demonstrates how to install a snap lock metal roof in our showroom.

Snap loc is self locking and watertight making it an appealing smart choice for new or re roofing projects.

Snap loc is the original metal roof for residential buildings.

Snap loc metal panels are a perfect fit for residential and many architectural and commercial applications.

Field seaming requires the joints at the panel edges be crimped together as each piece is installed on the roof.

This is the traditional installation method and it calls for some expensive specialty tools.